***z-above-h1.shtml***

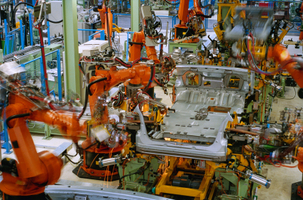

Manufacturing Cost Accounting

Manufacturing cost accounting refers to the process of gathering, maintaining and reporting product and plant costs. Every plant uses it no matter how small the operation is, however, some plants use it very informally.

MRP

System and Cost Maintenance:

- Normally a plant will have MRP (manufacturing resource

planning) software to run the cost system. This

system also runs the entire plants information needs.

- The Cost Accountant either reviews or maintains

the costs in the system. These costs are:

- Direct

Labor

- Material

Cost

- Burden

- Usually the materials department will maintain

the bill of materials (BOM). The BOM contains all the

purchase costs and amounts of material for each part.

- The direct labor is collected from time cards.

Either the direct labor employees or a clerk will enter the

time into the system.

- The burden costs are labor and plant

costs that the Cost Accountant allocates to a job or product.

- Management requires many different cost reports

so they can make informed decisions.

- The Cost Accountant creates reports from the

MRP

system. She will also create many unique reports as required.

- The cost reports will be used to:

- Notify Management of production problems.

- Help cost efficiency efforts

- Be used as a guide to bid on new work.

- Be used for budgeting and business plans